The Function of Industrial Scales in Quality Assurance and Guarantee

The Function of Industrial Scales in Quality Assurance and Guarantee

Blog Article

Exactly How Industrial Scales Improve Accuracy in Manufacturing and Logistics

By guaranteeing that products are weighed properly, companies can reduce errors that can lead to significant monetary repercussions. The advent of advanced innovations in evaluating systems is transforming traditional processes.

Value of Accuracy in Operations

In the realm of production and logistics, accuracy is the keystone of functional performance. Exact measurements are important for preserving quality assurance, enhancing source allowance, and making certain conformity with sector criteria. When procedures rely upon precise data, companies can minimize waste, improve production timelines, and boost total performance.

The value of accuracy prolongs past basic measurement; it likewise influences decision-making procedures. For circumstances, exact weight readings can identify suitable inventory degrees, enhance supply chain logistics, and promote exact invoicing. Inaccuracies in dimensions can lead to expensive mistakes, such as overproduction or underestimating material demands, which can jeopardize task timelines and success.

By applying rigorous measurement requirements, companies can recognize ineffectiveness and establish improvements, inevitably leading to enhanced customer contentment. Hence, spending in accuracy dimension devices, such as commercial ranges, is not simply a technological factor to consider however a critical necessary for success in the production and logistics sectors.

Kinds Of Industrial Scales

Different sorts of industrial scales play a crucial function in achieving the accuracy required for effective production and logistics procedures. Each type is made to meet specific needs, making certain exact measurement of products, materials, and parts.

One common kind is the platform range, which provides a level surface area for evaluating big items or bulk materials. These ranges are commonly utilized in storehouses and shipping centers. One more kind is the bench scale, generally smaller sized and used for considering private packages or smaller sized batches of items. These scales are crucial in quality assurance processes. Industrial Scales.

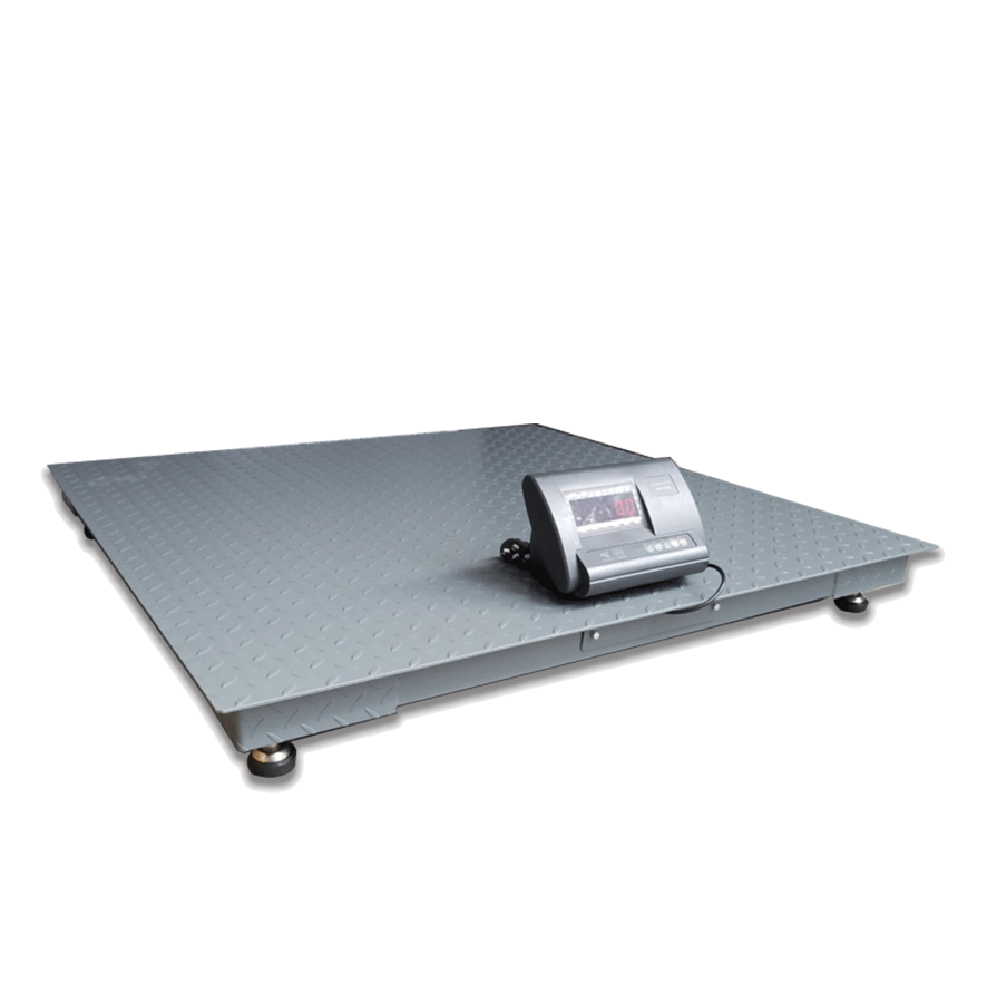

For applications where precision is crucial, logical balances are employed. These high-accuracy scales are utilized in laboratories and research study settings to gauge little amounts with utmost precision. Flooring ranges, created for sturdy considering, are perfect for weighing big pallets or containers, frequently incorporated with forklifts for performance.

Additionally, load cells are utilized in numerous applications for real-time weight dimension and information collection. Each of these scales contributes uniquely to the operational efficiency, making sure that organizations can keep precision throughout their production and logistics procedures. Recognizing the sorts of commercial ranges is essential for optimizing performance and achieving operational quality.

Effect on Supply Monitoring

Accurate weighing is important for reliable supply monitoring, as it straight influences stock accuracy and operational efficiency. In manufacturing and logistics, accurate dimension of products and items makes certain that supply documents reflect real supply degrees, decreasing discrepancies that can cause overstocking or stockouts. Industrial ranges give the needed accuracy to consider products accurately, allowing companies to maintain a reliable supply system.

Furthermore, exact considering adds to much better forecasting and planning. With exact data on stock levels, organizations can make educated choices pertaining to purchase and production timetables. This reduces the danger of excess stock, which can lock up funding and boost storage space prices, as well as prevent lacks that might interrupt operations.

Moreover, the integration of commercial scales with inventory administration systems facilitates real-time monitoring of stock motions. This simplifies the procedure of updating inventory documents, improving transparency and accountability throughout the supply chain. Ultimately, exact evaluating not only supports efficient supply management but likewise drives total functional performance, enabling organizations to respond promptly to market needs and keep a competitive edge in their corresponding markets.

Enhancing Quality Assurance

Efficient supply monitoring not only guarantees optimal stock levels but additionally lays the groundwork for robust top quality control processes. Industrial ranges play a pivotal function in enhancing top quality control by supplying accurate weight dimensions that are important for maintaining item honesty. Consistent weight verification allows makers to stick to specifications, ensuring that each product meets the necessary top quality requirements.

In high-stakes settings, such as food production or drugs, click to investigate also minor weight inconsistencies can lead to substantial conformity issues. By integrating industrial ranges right into the assembly line, business can keep an eye on item weights in genuine time, enabling immediate rehabilitative actions if irregularities are detected. This positive technique minimizes waste and improves overall item reliability.

In addition, accurate weighing promotes much better formula of basic materials, which is essential in sectors like cosmetics and chemicals. By making sure that component ratios remain regular, suppliers can achieve exceptional item top quality, improving client complete satisfaction and minimizing returns.

Future Trends in Evaluating Modern Technology

The future of considering innovation is positioned for significant improvements driven by automation, connectivity, and information analytics. As sectors develop, the assimilation of sophisticated sensing units and IoT (Web of Things) capabilities will certainly make it possible for real-time monitoring and coverage of weight information. This connectivity will certainly not just enhance functional effectiveness yet additionally help with predictive upkeep, reducing downtime and enhancing performance.

Furthermore, the unification of expert system and artificial intelligence formulas right into considering systems will certainly enhance information analysis abilities. These innovations can identify anomalies and patterns, enabling more informed decision-making and enhanced supply chain administration. The rise of cloud-based options will enable seamless data sharing throughout platforms, making certain that stakeholders have accessibility to current information at all times.

Sustainability will certainly additionally play a vital duty in future considering technology. As businesses aim to lessen their carbon footprint, weighing systems that integrate energy-efficient designs and products will certainly become progressively vital. In addition, innovations in digital evaluating scales will sustain much better source management by offering specific dimensions that lower waste.

Conclusion

Finally, industrial ranges significantly improve accuracy in manufacturing and logistics by giving specific weight measurements vital for effective procedures. Their duty in supply administration, quality assurance, and integration with sophisticated innovations emphasizes their significance in optimizing and reducing look at this now discrepancies source allotment. As sectors continue to develop, the adoption of ingenious weighing services will additionally sustain operational effectiveness and decrease waste, ultimately adding to boosted productivity and competitiveness in the marketplace.

One common kind is the system range, which supplies a flat surface area for evaluating bulk materials or big items. An additional kind is the bench scale, generally smaller and utilized for evaluating private packages or smaller batches of items. Floor scales, created for heavy-duty evaluating, are suitable for considering huge pallets or containers, commonly incorporated with forklifts for efficiency.

Industrial scales provide the essential precision to weigh items properly, enabling services to preserve a trusted supply system.

Report this page